In response to Melissa’s comment about embedding the finding for an enameled piece, I thought I would add a few images as to how I do this for welding, then enameling. I am trying something new and this is how I do it.

First, of course, I fabricate the pin back finding. For a vertical piece I use a “barrette” style pin back. After I make the findings, I hard or IT solder wires into tiny holes that I have drilled into the back of the findings. In some cases, I use pins that go through form front to back to avoid soldering that could melt during enameling process. I then feed the wires through matching holes that I have drilled into the back of the brooch before welding. Before I do that, I chase a seat for the finding so that there is a place for it to rest and a place for the enamel to pool around the finding.

I then turn over the piece so that the wires are exposed and with a mini torch, I ball up the wires until they lay flush with the interior surface. I then weld the two halves together and enamel. The most difficult part of this is to weld the copper without melting the silver findings as the melt temperatures between silver and copper are so different.

placing findings before attaching

balled up wires on the interior before welding

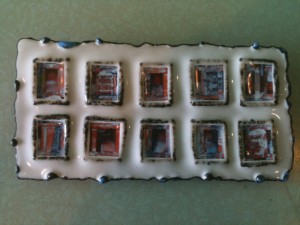

exterior with findings before welding

front of brooch after enameling and before etching

brooch, before welding-how to protect findings

front of brooch after enaneling and before etchingback of brooch with findings-before clean-up and etching

Kathleen Browne

Kathleen Browne is an artist and educator from the USA who featured in our first Heat Exchange edition in 2012, and is back for the 2015 exhibition.