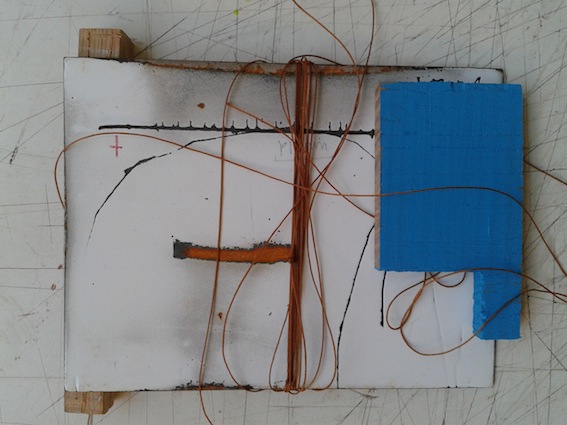

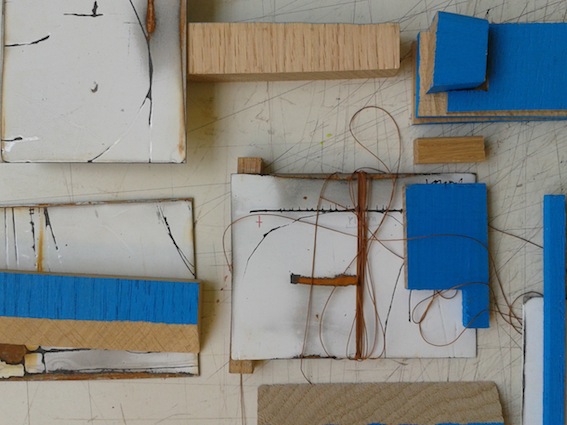

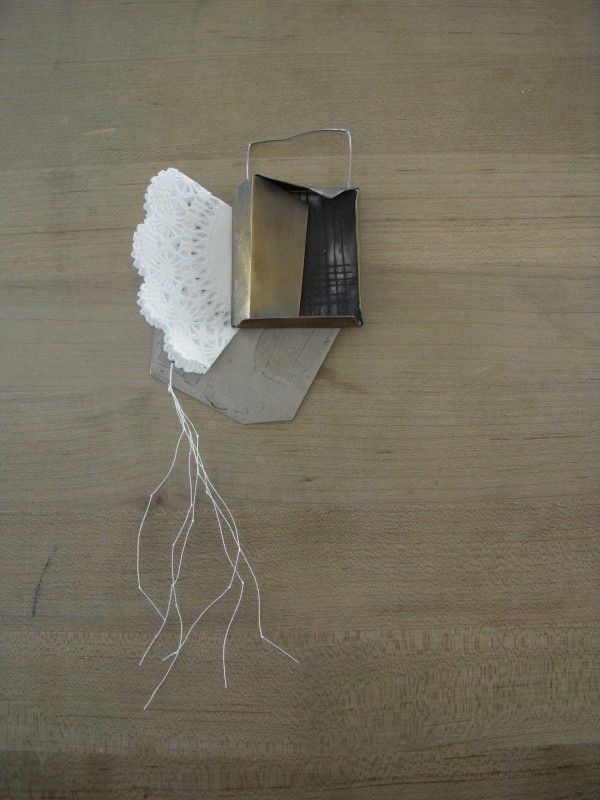

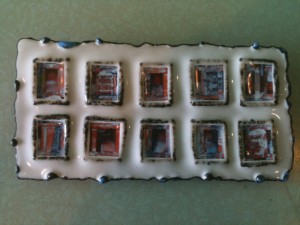

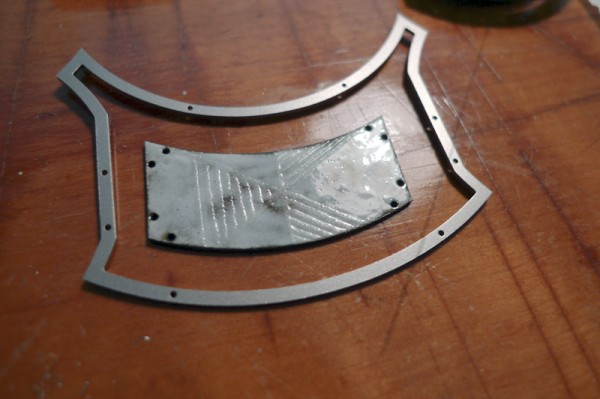

There was the jewellery bench and the enamel desk in my St Kilda studio. At any time there could be a pile of metal on the enamel bench ready to go, as well as (and fed directly from this pile) a stack of enamelled segments on the jewellery bench, awaiting stringing into a single piece. By the end of my progress in making works for this exhibition, enameling and making days would alternate, which allowed my studio to cool down between firing days. It also meant that I would have to concentrate hard and think creatively on enamelling days, while on making days more dexterity, but less imagination, was needed to complete the pieces. By this point, the tethering points and fixing methods I was planning to use had been decided, just the work of ordering and joining remained.

Melissa Cameron

Melissa is a jewellery artist from Australia living in Seattle in the US. Her works can be found in the National Gallery of Australia as well as the Cheongju City Collection in South Korea. Her enamel works typically display subtle enamel incursions amidst precise laser cut stainless steel layers.

- Web |

- Google+ |

- More Posts (26)