These are my tools for silversmithing. Some are selfmade. It took some time to realize, which ones I really need for my work.

I’ve been lurking at Heat Exchange2 for a while now, and after the latest request for a post, I decided to gather my thoughts on how my work was coming along.

The inspiration for my installation “Housing/Warehousing” evolved over nearly a year’s time. Over the years I have returned to a house theme from time to time, sometimes for personal reasons, but also because home and shelter are universal themes. The sequence of events went something like this: At the Bauhaus Museum in Tel Aviv I saw colorful workingmen’s houses designed by Bruno Taut, who was forced to leave Germany by the early 1930s. On a retreat I talked with woodworker Wendy Maruyama, who was beginning her monumental “Tag Project,” about the Japanese detention camps in the US during the same war. Investigating abandoned buildings I was struck by the similarity in structures used to house prisoners at Auschwitz and Manzanar.

I began constructing peaked-roof dwellings that were folded up from a single sheet of metal, using vitreous enamel to give a permanent, rich surface. Using wire to “stitch” them together at the seam gave a surgical as well as domestic subtext, and was a sign that they had been fabricated by hand. Scaling up beyond jewelry made every one a technical challenge as I went along. Recurring issues concerned using sifted or liquid enamel, often both; getting the right chalky, gouache-like surface; and the optimal relation between metal gauge and final dimensions.

Then an unexpected layer of meaning came into the work. Riding the train from Munich to Dachau last spring, I noticed the landscape was dotted with small, colorful, peaked-roof houses, much like the ones I had been making. The geographical and cultural proximity of these structures tied together the two previously irreconcilable bodies of work. Taut’s houses, while modest in scale, were full of life; barracks used to warehouse people are the opposite.

On yet another level, I had long tried to find a way to address the Holocaust in my work, but jewelry just wasn’t it. The opportunity and, yes, deadline of Heat Exchange2 enabled me to create the space to explore my own narrative.

Hello, it has been a while. When I received a notification-email, I read the articles through emails and have been quite satisfied. But surely there is more, sorry! I have to get used to “exchange”. I still need to learn little more about the site to orientate myself with comments-things…

Meanwhile, as a new year has begun, I will start to put some so called “inspiration”- materials. I am not yet sure if they will be something. I almost never transform some exact inspiration directly into my work. But the layers of inspirations are effecting the process of making.

I get inspirations from all over, so my layers of inspiration are not well organized. Some are factual, others are abstract. Please don’t ask me how they associate each other… I don’t know yet, either.

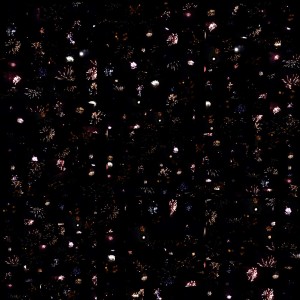

These are very concrete motives. Continuing, repeating, lining things often catch my eyes, though I haven’t be able to do so with my work, yet.

Colours are always inspiring.

Even more dense.

Enjoy your weekend!

Kaori

So I’m working on another exhibition at the moment, for which I’ve produced these sample squares of a new pattern. A friend of mine, the head of jewellery and objects at Slippery Rock University in Pensylvania, Sean Macmillan, got in contact with me to see if I would be interested in collaborating with him for the Co:operation GARNISH exhibition. This show, being curated by Rachel Timmins and Brigitte Martin, is meant to be a collaboration of unlike forces aimed at building links between a fairly disparate jewellery community here in the US. After some initial discussions about our suitability to pair up (we are technically both metalsmiths) we decided that a large-sculpture-making, techno-challenged academic in Slippery Rock and a delicate-jewellery-making, CAD-using, basement-studio-hermit from Australia now living in Seattle was about as different as we needed to be!

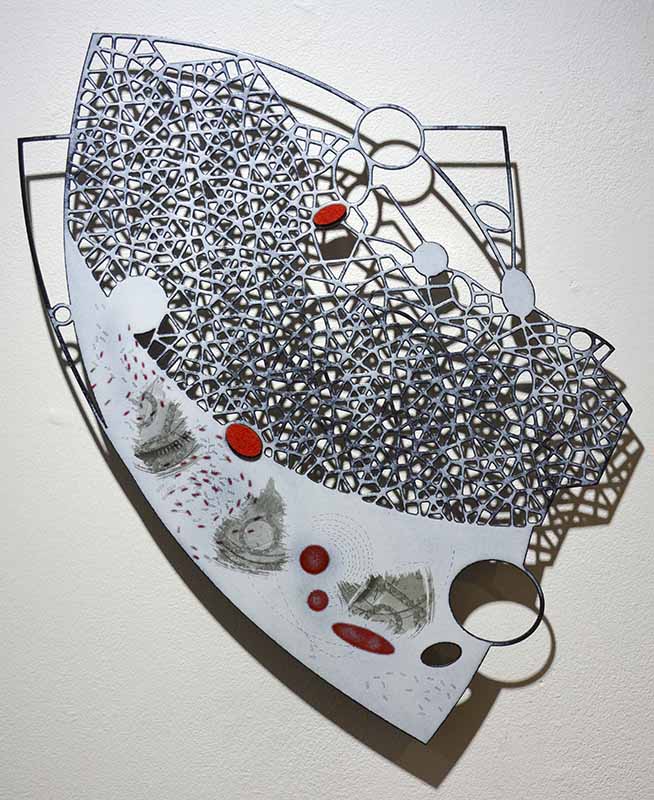

Ttrue to my usual method, I got straight into drawing a pattern in Cad, which we had both agreed over a long text-message conversation, needed to be ‘lacy’ (see images). And true to his, Sean soon texted me a mobile-phone image of his hand-built model, a roughly sketched and assembled pattern – in the way of a garment pattern – made out of used computer-paper and masking-tape.

Cut to a few months later, and here are some images of the sample squares of pattern that I’ve had cut, checked out and then sent off to Sean to play with. (Notice the miscommunication with the laser-cutters resulted in the lead-ins being on the wrong side of the line – we’re after the sheet more than the ‘drop-outs’ in this instance as that’s what Sean will work with.)

And here’s the first test works! These necklaces are in stainless steel and vitreous enamel with titanium hinge pins. As test pieces – a sort of proof of concept – I think they are pretty successful.

The actual part that will allow Sean to work his magic was signed off by us today, and will be cut by Pololu early next week. Once Sean has the pieces he will send me all of these inserts and I’ll have some more enamelling to do!

Our time in Erfurt was great; a harmonious and creative sharing of workshop space and time to reflect. I love Melissa’s sensitive ‘sound scapes’ posts on this Blog; it is one of my prevailing memories: the gentle sound of abrading, ‘squishing’ the screen, tapping, the sound of Ramon and Silvia sawing in the jewellery workshop. All the sounds of busy artists creating work, focusing on the materials. I am also very excited to see Silvia and Ramon’s pieces finished and how they developed after Erfurt in the studio in Barcelona.

Beautiful work, dear Silvia and Ramon!

My own work in Erfurt attempted to explore the ‘drawing breaking out of the frame’, which made the laser cut metal pieces fragile and the firing process precarious. I had some technical problems with tension in the metal and enamel and consequently warping, so overall a challenging experience. Thankfully there were some pieces, which made it through the many making stages almost as I intended.

Now I am in the process of researching my new direction and I will write about this as it grows. In July 2014 I was awarded an Arts Council of Wales grant to develop a new body of work for a solo exhibition in 2016 and of course, Heat Exchange 2, in 2015. This grant will start in January 2015, which gives me a little ‘breather’ to think and identify my direction.

There is a focus of course, which has been running through my work since I began making ceramics in the 1980s: an interest in the space in-between (all my work is always endlessly cut and pierced), rhythm, movement, chaos and activating space. I would now like to see this conceptual interest reflected in the making process by exploring rhythmical processes such as laser engraving (horizontal movement, embedding an image into the enamel), exploring the jacquard loom (again the horizontal weaving process) and 3D printing.

3D printing is also one such ‘rhythmical’ process, minutely building up layers, reminiscent of the weaving process. In April 2014 I carried out a 3D printing residency at the Product Development and Research Centre at Cardiff Metropolitan University and I can see the potential of the pieces I created there. For me this is a step into the direction of ‘activating space’, taking the 2D piece off the wall, producing a smaller 3D companion. I am very curious to know what will happen and whether this ‘process’ will be right for me. At the moment I am trying to learn Rhino and finding it surprisingly hard.

So, this is where I am now; very exciting. I would love to hear from you all, where you are in your work, what you are thinking?

Sorry for the radio silence from this end – I’ve not been in the office much of late – I’ve been in the basement, making things out of all of the enamelled pieces I brought back from Erfurt with me (and sandblasting back one errant piece that never quite found what colour it wanted to be.)

This pic is taken of a bunch of brooch backs that were prepped ready to be sandblasted back with glass beads. The pins were polished up before welding, so I enlisted the fingers of a latex glove to save the shiny pins from any misdirected sprays of the blast nozzle.

The obverse was then covered in masking tape to protect the enamelled side from the same. The ‘front’ sides were not intended to be lifted from the mesh floor on the interior of the blast cabinet, but you can never be to careful with the sandblaster – the air pressure alone had a tendency to knock things around.

I’m taking a break from posting sounds this week, to share a couple more photos from Erfurt. In these Gudrun is working, and Kaori is thinking while Elizabeth is cutting, then explaining.

I practiced Gudrun’s name in my head and out loud to myself, many, many times while I was in Germany. I can’t speak any German, apart from ‘Hallo’, ‘genau’ and ‘Tschüss,’ which I picked up around the studio. Oh, and the translations of “Can I have two beers, please?” and “I am allergic to nuts.” for their obvious importance (though I generally replace the word ‘beer’ with ‘whiskey’, which fortunately doesn’t need translation…)

Anyway, I was talking about Gudrun.

Her name is a good word to try and perfect the ‘R’ sound that is needed to speak German correctly (or, as was my aim, with fewer unforced errors). I tend to make a rolled ‘errrr’ like I was taught for Italian, but that’s not right, and a bit of a hindrance actually. So in trying to get the right ‘R’, I found having it in the middle of a word was helping with the momentum needed to get the ‘R’ cor-rect. So what better word than the name of the person on the table next to you?

Fortunately no one was following me around with a sound recording device, listening in as I muttered “Gud-run.” to myself. Over and over and over again.

As mentioned in my last post, I was collecting sounds as well as enamelling steel while I was in Erfurt.

Let me introduce our second Friend of Heat Exchange, Martin Schulze, properly. Here is a video of him screen printing, in this instance it’s directly onto a found steel object that he had pre-enamelled.

Once again, aeroplane noise just about scuttled the recording…

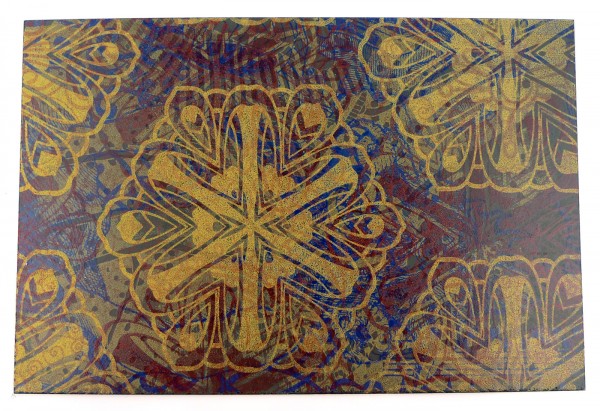

Martin fearlessly led two expeditions to the scrap metal yard, and picked himself up some great pieces to work on, so a lot of what you see in the image below uses this carefully mined booty. He brought all these wonderfully shaped bits into the studio, cleaned and pre-enamelled them before he screen-printed directly onto the surface, multiple times in many cases. (Be sure to click on the image to see the intricate line-work of his drawings, as translated onto screen and then into the enamel.)

Seeing my love of pattern (which, he pointed out, was as equally discernible in my work as my wardrobe) he was kind enough to give me one of his postcards that feature complimentary layers of differing patterns.

You can see a single sample of his work via his 850grad website.