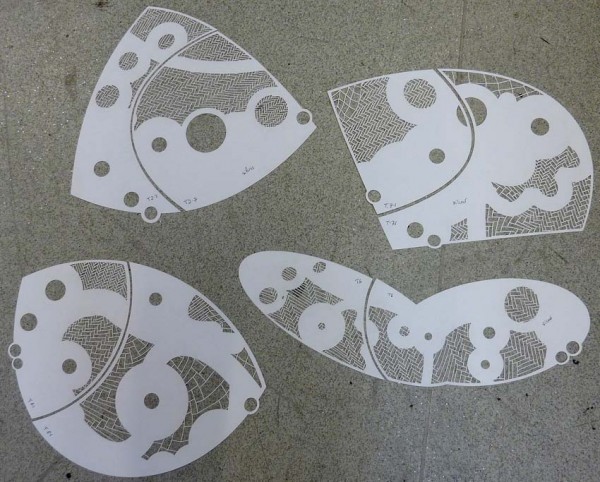

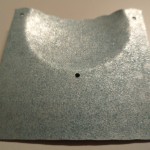

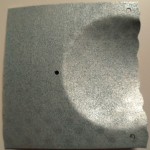

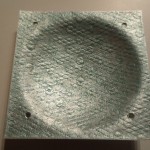

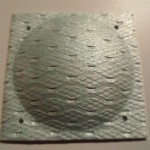

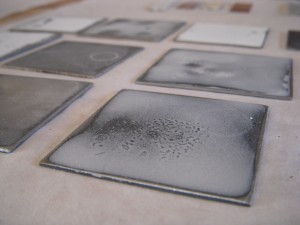

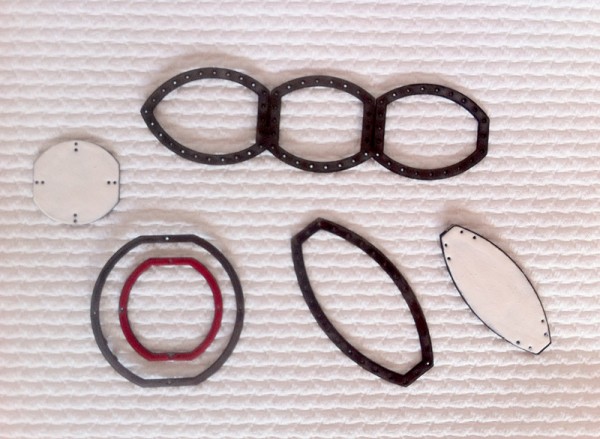

So back here I was waxing lyrical about the parts I was enamelling to put together a bunch of brooches. The image below was taken shortly after the image in that post, and shows the three inserts that I didn’t show before, mid way through enamelling. On the left-hand-side it also shows the centre piece of the work Blue Radical Axis, with the shot taken after applying a clear coat over the graphite, and before adding colour.

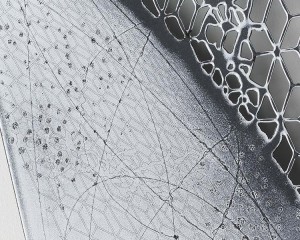

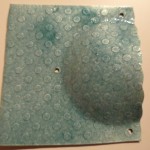

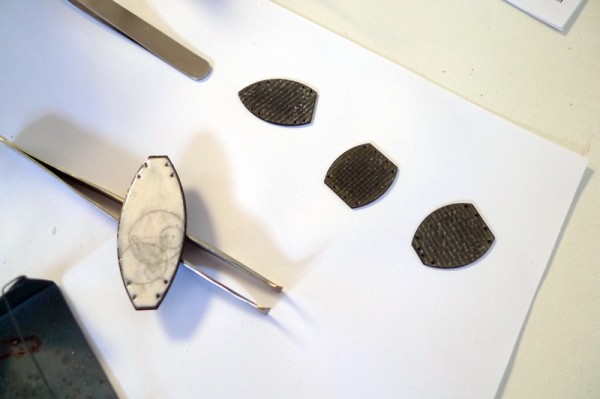

The three pieces on the right have each had a clear coat of liquid enamel, and then two layers of linework applied, layer by layer. The lines, first drawn in pen, have been covered in sandblasting grit with the remainder of the grit shaken off, so that just the slim slivers remain, which are then fired on (a technique borrowed from Elizabeth). Now, I say grit, but these are actually Ballotini glass spheres, of a very tiny size, that I would normally use to get a bright (almost polished looking) surface on metal in my sandblaster. They impart more of a texture than a colour, as they fire pretty clear.

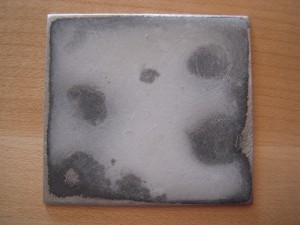

The final layers of enamel on this piece, which happened after this photo, were lines again drawn (3 lines in different directions, to represent x, y and z axes) but this time covered in regular white enamel, so that the topmost layer would have the most effect. Finally, the one representing ‘z’ received a thin coat of red.